Corrugated Materials: Boxes vs. Sheets vs. Rolls

Corrugated Materials: Boxes vs. Sheets vs. Rolls

Corrugated packaging can be used to protect, store, or carry all types of materials including electronics, food, pharmaceuticals, fragile items and/or liquid. Corrugated material is reusable and recyclable, which makes it an excellent sustainable packaging choice.

Corrugated material is made from three layers of kraft paper. The outer two layers are flat strips of thick kraft paper. The middle layer is made of a wavy piece of kraft paper that creates air that act as a cushion. This middle layer is created through a process called fluting.

What Determines the Thickenss of Corrugate?

Corrugated material is available in different thicknesses. When shopping for corrugated, you can tell how thick the material is by its flute size. Flute size is determined by thickness & number of flutes per foot. Flutes per foot measures the space between the waves of the middle layer of kraft paper. Less flutes per foot means larger waves and greater thickness, which equates to more cushioning. Flute sizes range from A-F, with A being the thickest and fewest flutes per foot.

A Flute: 1/4” thick, 36 flutes per foot

B Flute: 1/8” thick, 49 flutes per foot

C Flute: 3/16” thick, 41 flutes per foot

D Flute: 9/100” thick, 63 flutes per foot

E Flute: 1/16” thick, 90 flutes per foot

F Flute: 1/32” thick, 125 flutes per foot

Types of Corrugated Materials:

Corrugated Boxes

The three most common distinctions of corrugated boxes are single wall, double wall, and multi-depth. Check out our recent article for more detailed information about corrugated boxes.

Gaylord Boxes

Gaylord boxes are large and sturdy. They are made for storing or transporting large product or large amounts of product. They are sometimes referred to as pallet boxes, as they are made to be the size of a pallet. Gaylord boxes can fit neatly on top of a pallet to create corrugated walls that surround the pallet providing it with protection on all sides. These boxes are popular in warehouses, grocery stores, and other areas where you may need to store or move large amounts of product. Lids for gaylord boxes are available as well, but are typically sold separately.

Corrugated Sheets

Corrugated sheets are used for stability when stacking materials on top of one another. For example, if someone is shipping a skid of steel strapping on a pallet, they will need to stack the steel coils on top of each other. Putting a corrugated sheet between each roll of strapping creates a neat layer, provides additional stability, and helps protect the coils from damaging during transport or while in storage.

Corrugated sheets do a great job protecting the top and bottom of a product, but do not necessarily protect the sides. They are most helpful when stacking uniform product such as coils, or any stackable material that a corrugated sheet can be laid flat on top of. Corrugated sheets can be used for protecting or stacking layers within a corrugated box or container as well.

Corrugated Strips

Corrugated strips are the same as corrugated sheets in thickness & material, however, are much longer and skinnier. Corrugated strips are available in different lengths, but for reference, a commonly used corrugated strip is 4 x 48”.

Corrugated Rolls

Corrugated rolls are ideal for irregular or difficult to wrap items. Unlike corrugated sheets, corrugated rolls can be used on material that is non-uniform and will protect all sides of an item. Corrugated rolls are more flexible for the user, as they can more easily be cut to a desired size. In practice, rolls are wrapped around an item as many times as needed to create a ‘corrugated box with no corners’ to protect the material.

Corrugated Mailers

Corrugated mailers, often called industrial mailers or kraft mailers, are a lightweight & tear resistant packaging option perfect for shipping small, lightweight, and fragile items. These crush resistant mailers are folded to create a double walled corrugated container with protection on all sides. They provide cushion for your products making them great for long-distance shipping. Kraft mailers fold together in seconds and require no tape, glue, or staples to hold together. The edges of these mailers have a unique “wave-rule” edge which virtually eliminates the possibility of paper cuts making them extremely user-friendly and safe. Kraft mailers come in various sizes for shipping all different types of product. White Die Cut Mailers, Kraft Die Cut Mailers, and Jumbo Mailers are a few of the most popular styles of mailers.

How to Fold a Corrugated Mailer?

In most cases, corrugated mailers come unassembled. They are fairly straightforward to fold, and often times will come with directions. Here are the basic steps to assembling a common corrugated mailer.

Step 1: Lay the box flatly on the ground so that the creases face upwards. Start by folding the 2 long sides of the box inward

Step 2: Lay the long, folded sides of the box down flat, then fold upwards at the crease shown in the picture. Keep the box upright as shown

Step 3: Fold two of the upright flaps inward to create the sides of the box

Step 4: Hold box in place as shown in picture

Step 5: Fold the last remaining side of the box inward

Step 6: Tuck the 2 side flaps inside of the box to create the final walls

Step 7: Fold both of the side flaps down into place within the box

Step 8: This is how the corrugated mailer should look when it is opened

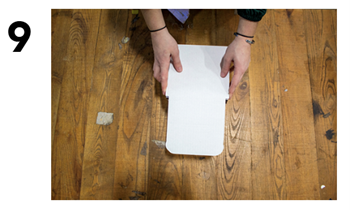

Step 9: Begin closing the corrugated mailer by folding the back of the box over top of the opening to create the lid

Step 10: Close the corrugated mailer by tucking the final flap into the open slit on the front of the box

When done properly, corrugated mailers require no glue, tape, or staples.

Corrugated material comes in all different styles and sizes. If you are interesting is purchasing corrugated material, or if you have questions regarding a specific product, please reach out to one of our product experts.